Di cîhana sîstemên boriyan de,girêdanroleke girîng di girêdana boriyan û misogerkirina herikîna bênavber a şilek an gazan de dilîzin. Wekî hilberînerek pêşeng di pîşesaziyê de,CZITDevelopment Co., Ltd ji bo dabînkirina pêvekên bi kalîte bilind, ji bo pêkanîna hewcedariyên cihêreng ên xerîdarên me veqetandî ye. Di vê blogê de, em ê li ser cûdahiyên di navbera pêveka bi têl û pêveka soketê de kûr bibin, û ronî bikin ser taybetmendî û sepanên wan ên bêhempa.

Kopiyên bi têl, wekî ku ji navê wê jî diyar e, li hundir an derveyî hevgirêdanê têl hene, ku dihêle ew ji bo girêdanek ewle li ser dawiya lûleyan werin pêçandin. Ev celeb hevgirêdan bi gelemperî di sepanên zexta nizm de tê bikar anîn û bi hêsaniya sazkirin û veqetandina xwe tê zanîn. Sêwirana têlkirî mohrek pêbawer peyda dike, ku wê ji bo pergalên ku pêşîlêgirtina rijandinê girîng e minasib dike.

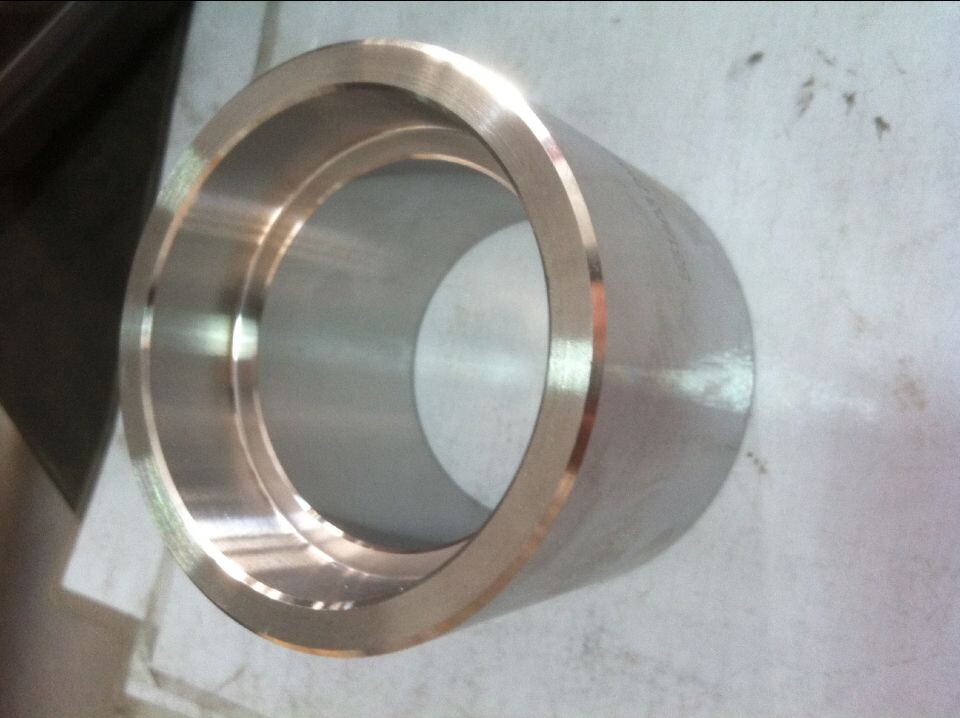

Ji alîyek dî,girêdana soketê, ku wekî hevgirêdana weldkirina soketê jî tê zanîn, ji bo ku li ser dawiya lûleyê bicîh bibe hatiye sêwirandin û bi karanîna weldkirina fîletî tê weldkirin. Berevajî hevgirêdanên bi têlan, hevgirêdanên soketê ji bo girêdanê bi têlan ve girêdayî nînin, ev yek wan ji bo sepanên zext û germahiya bilind îdeal dike. Girêdana weldkirî girêdanek xurt û mayînde peyda dike, ku di şert û mercên dijwar de yekparebûna pergala lûleyan misoger dike.

Her çend hem pêvekên bi têl û hem jî yên soket ji bo girêdana lûleyan xizmetê dikin jî, taybetmendiyên wan ên cihêreng wan ji bo hawîrdor û hewcedariyên cûda guncan dikin. Pêvekên bi têl ji bo sazkirinên bilez guncan in û bi gelemperî di pergalên zexta nizm de têne bikar anîn, lê pêvekên soket ji ber xurtbûn û pêbaweriya xwe di sepanên zexta bilind û germahiya bilind de têne tercîh kirin.

BaCZITDevelopment Co., Ltd, em girîngiya hilbijartina pêveka rast ji bo hewcedariyên we yên taybetî fam dikin. Rêzeya pêvekên me, di nav de vebijarkên qayimkirina bi têl û soket, li gorî standardên herî bilind têne çêkirin da ku performans û domdariya bêhempa di mîhengên pîşesaziyê yên cûrbecûr de misoger bikin.

Di encamê de, têgihîştina cûdahiyên di navbera hevgirêdana bi têl û hevgirêdana soketê de ji bo hilbijartina vebijarka herî guncaw ji bo pergala boriyên we girîng e. Çi hûn ji bo sepanên zexta nizm an zexta bilind hevgirêdanan hewce bikin,CZITDevelopment Co., Ltd şirîkê we yê pêbawer e ji bo couplingên bi kalîte bilind ku taybetmendiyên we yên rast bicîh tînin.

Dema weşandinê: 19ê Tîrmehê-2024